If you are new to the craft beer industry, die-cutting may be an unfamiliar term. Die-cutting has its origins in letterpress printing, and it evolved to become a more specific manufacturing process. The die-cutting process in packaging utilizes a die to cut materials into an array of different shapes, designs and patterns.

This process allows us to create unique custom packaging tailored to your brand narratives and customer experience. If you are looking for unique and custom packaging to wow your customers, read on about the die-cutting process and if it’s right for you.

What’s a Die?

A die is a specialized tool used to cut and shape packaging materials using a press.

You can think of a die as a ‘mold’ that is shaped in the specific way needed to cut out your custom packaging. The die will cut out the packaging and remove the excess material. Using a die cut allows for an array of options for shapes and styles. Utilizing die cuts, scores, punched holes, partial cuts, and perforations, our team can create a variety of beautifully decorated structural and ornamental folding carton designs.

A die is created using tools and die makers to form your custom die before mounting it onto a press.

At this point you want to have your dieline finalized to start die-cutting your first batch of custom packaging.

Die cutting is perfect for high-volume orders and is extremely efficient. Custom dies can be costly at first, but will last a long time.

How is a Die Made?

In order to make a die we need an electronic rendering of the layout of the packaging, including:

- Sizes

- Folds

- PerforationScoring/Creasing/Cut

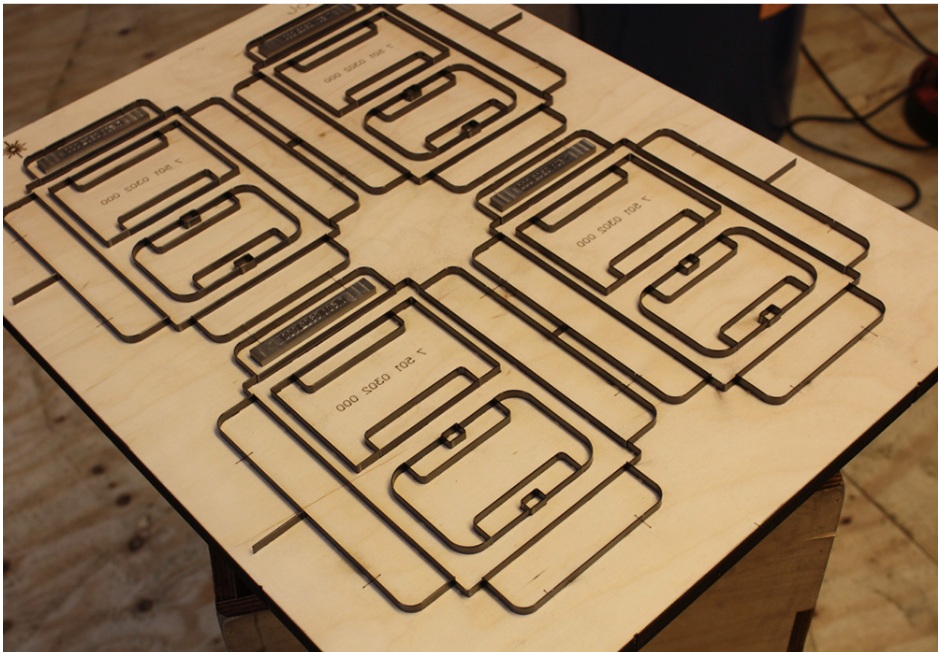

Once we have the render, a CNC router will cut the wood to shape. To get the desired result, specs are collected based on the type and thickness of steel that is needed in each area.

The steel rules (cutting tools) that will cut your packaging are sent through a machine to make then the size and shape needed for your custom packaging. These new steel cutters are manually inserted into the original routed board in specified locations.

Once all the cutting tools are in place, foam rubber pieces are placed along the die to help the tools form to the packaging material to cut and/or shape your box.

Our team will test the die to make sure your custom packaging is the correct shape. Next, we move to the branding phase!

Crafted Box Co and Die Cutting

Our die-cutting department features a variety of die-cutting presses that allow us the flexibility to select the right press for the job.

Die cutting requires consultation with experts. We offer the latest in die-cutting technology, combining automation with precision. All of our cutting dies and counter plates are made in-house by the skilful hands of experienced craftsmen, ensuring the accuracy of each die. Reverse half cuts, cut creases and reverse scoring methods allow for folding cartons to be cut and folded into intricate shapes.

We love the die-cutting process because it allows you to give a pleasant first experience with your brand. Packaging should never be overlooked in the craft beer industry. Using a die is a great way to invest in quality packaging. If you want to learn more about your packaging options then contact us today for a free quote.